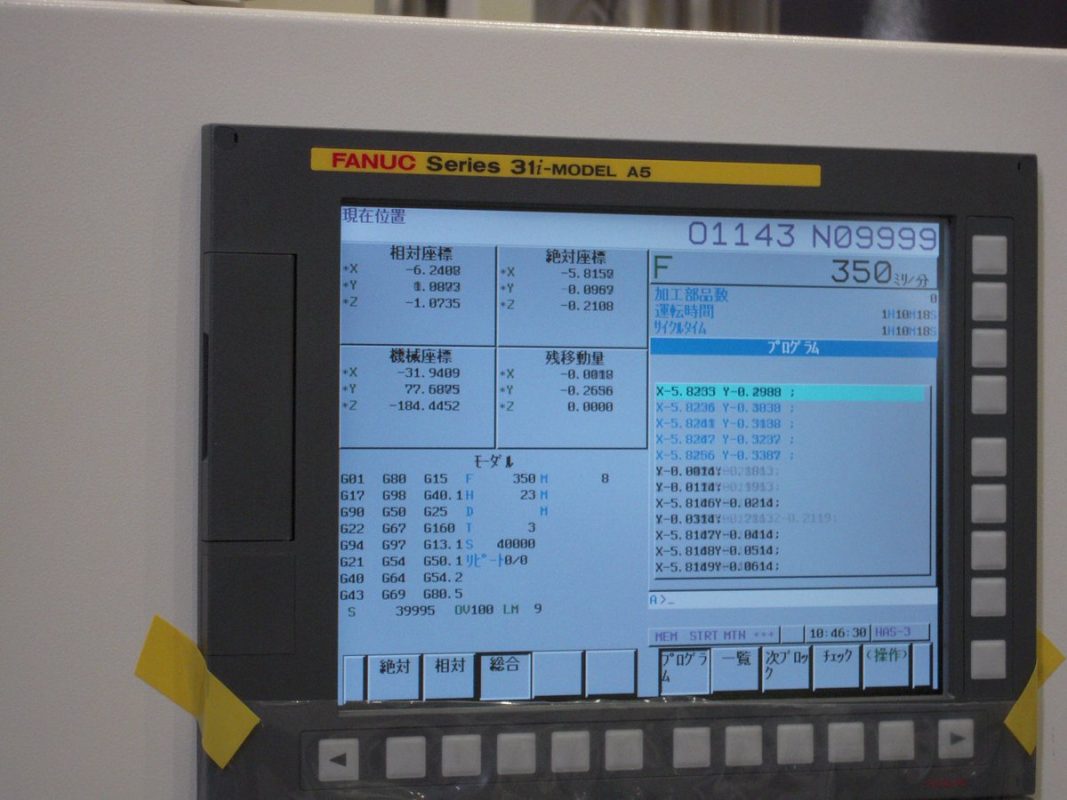

Giới thiệu mã lệnh G code cho bộ điều khiển Fanuc 30 31 32

Lệnh G Code Fanuc 30 31 32

Following list of g codes applies to following cnc controls as well.

- Fanuc Series 30i/300i/300is-MODEL A

- Fanuc Series 31i/310i/310is-MODEL A5

- Fanuc Series 31i/310i/310is-MODEL A

- Fanuc Series 32i/320i/320is-MODEL A

Lệnh G Code Fanuc 30 31 32 chi tiết

| G Code | Description |

|---|---|

| G00 | Positioning (rapid traverse) |

| G01 | Linear interpolation (cutting feed) |

| G02 | Circular interpolation CW or helical interpolation CW |

| G03 | Circular interpolation CCW or helical interpolation CCW |

| G02.2, G03.2 | Involute interpolation CW/CCW |

| G02.3, G03.3 | Exponential interpolation CW/CCW |

| G02.4, G03.4 | Three-dimensional coordinate conversion CW/CCW |

| G04 | Dwell |

| G05 | AI contour control (high-precision contour control compatible command) |

| G05.1 | AI contour control / Nano smoothing / Smooth interpolation |

| G05.4 | HRV3,4 on/off |

| G06.2 | NURBS interpolation |

| G07 | Hypothetical axis interpolation |

| G07.1 (G107) | Cylindrical interpolation |

| G08 | AI contour control (advanced preview control compatible command) |

| G09 | Exact stop |

| G10 | Programmable data input |

| G10.6 | Tool retract and recover |

| G10.9 | Programmable switching of diameter/radius specification |

| G11 | Programmable data input mode cancel |

| G12.1 | Polar coordinate interpolation mode |

| G13.1 | Polar coordinate interpolation cancel mode |

| G15 | Polar coordinates command cancel |

| G16 | Polar coordinates command |

| G17 | XY plane selection |

| G18 | ZX plane selection |

| G19 | YZ plane selection |

| G20 (G70) | Input in inch |

| G21 (G71) | Input in mm |

| G22 | Stored stroke check function on |

| G23 | Stored stroke check function off |

| G25 | Spindle speed fluctuation detection off |

| G26 | Spindle speed fluctuation detection on |

| G27 | Reference position return check |

| G28 | Automatic return to reference position |

| G29 | Movement from reference position |

| G30 | 2nd, 3rd and 4th reference position return |

| G30.1 | Floating reference position return |

| G31 | Skip function |

| G31.8 | EGB-axis skip |

| G33 | Threading |

| G34 | Variable lead threading |

| G35 | Circular threading CW |

| G36 | Circular threading CCW |

| G37 | Automatic tool length measurement |

| G38 | Cutter or tool nose radius compensation : preserve vector |

| G39 | Cutter or tool nose radius compensation : corner circular interpolation |

| G40 | Cutter or tool nose radius compensation : cancel Three-dimensional cutter compensation : cancel |

| G41 | Cutter or tool nose radius compensation : left Three-dimensional cutter compensation : left |

| G41.2 | Cutter compensation for 5-axis machining : left (type 1) |

| G41.3 | Cutter compensation for 5-axis machining : (leading edge offset) |

| G41.4 | Cutter compensation for 5-axis machining : left (type 1) (FS16i-compatible command) |

| G41.5 | Cutter compensation for 5-axis machining : left (type 1) (FS16i-compatible command) |

| G41.6 | Cutter compensation for 5-axis machining : left (type 2) |

| G42 | Cutter or tool nose radius compensation : right Three-dimensional cutter compensation : right |

| G42.2 | Cutter compensation for 5-axis machining : right (type 1) |

| G42.4 | Cutter compensation for 5-axis machining : right (type 1) (FS16i-compatible command) |

| G42.5 | Cutter compensation for 5-axis machining : right (type 1) (FS16i-compatible command) |

| G42.6 | Cutter compensation for 5-axis machining : right (type 2) |

| G40.1 | Normal direction control cancel mode |

| G41.1 | Normal direction control on : right |

| G42.1 | Normal direction control on : left |

| G43 | Tool length compensation + |

| G44 | Tool length compensation – |

| G43.1 | Tool length compensation in tool axis direction |

| G43.4 | Tool center point control (type 1) |

| G43.5 | Tool center point control (type 2) |

| G45 | Tool offset increase |

| G46 | Tool offset decrease |

| G47 | Tool offset double increase |

| G48 | Tool offset double decrease |

| G49 (G49.1) | Tool length compensation cancel |

| G50 | Scaling cancel |

| G51 | Scaling |

| G50.1 | Programmable mirror image cancel |

| G51.1 | Programmable mirror image |

| G50.2 | Polygon turning cancel |

| G51.2 | Polygon turning |

| G52 | Local coordinate system setting |

| G53 | Machine coordinate system setting |

| G53.1 | Tool axis direction control |

| G54 (G54.1) | Workpiece coordinate system 1 selection |

| G55 | Workpiece coordinate system 2 selection |

| G56 | Workpiece coordinate system 3 selection |

| G57 | Workpiece coordinate system 4 selection |

| G58 | Workpiece coordinate system 5 selection |

| G59 | Workpiece coordinate system 6 selection |

| G60 | Single direction positioning |

| G61 | Exact stop mode |

| G62 | Automatic corner override |

| G63 | Tapping mode |

| G64 | Cutting mode |

| G65 | Macro call |

| G66 | Macro modal call A |

| G66.1 | Macro modal call B |

| G67 | Macro modal call A/B cancel |

| G68 | Coordinate system rotation start or 3-dimensional coordinate conversion mode on |

| G69 | Coordinate system rotation cancel or 3-dimensional coordinate conversion mode off |

| G68.2 | Feature coordinate system selection |

| G72.1 | Figure copy (rotation copy) |

| G72.2 | Figure copy (linear copy) |

| G73 | Peck drilling cycle |

| G74 | Left-handed tapping cycle |

| G76 | Fine boring cycle |

| G80 | Canned cycle cancel |

| G80.5 | Electronic gear box 2 pair: synchronization cancellation |

| G80.8 | Electronic gear box: synchronization cancellation |

| G81 | Drilling cycle or spot boring cycle |

| G81.1 | Chopping |

| G81.5 | Electronic gear box 2 pair: synchronization start |

| G81.8 | Electronic gear box: synchronization start |

| G82 | Drilling cycle or counter boring cycle |

| G83 | Peck drilling cycle |

| G84 | Tapping cycle |

| G84.2 | Rigid tapping cycle (FS15 format) |

| G84.3 | Left-handed rigid tapping cycle (FS15 format) |

| G85 | Boring cycle |

| G86 | Boring cycle |

| G87 | Back boring cycle |

| G88 | Boring cycle |

| G89 | Boring cycle |

| G90 | Absolute programming |

| G91 | Incremental programming |

| G91.1 | Checking the maximum incremental amount specified |

| G92 | Setting for workpiece coordinate system or clamp at maximum spindle speed |

| G92.1 | Workpiece coordinate system preset |

| G93 | Inverse time feed |

| G94 | Feed per minute |

| G95 | Feed per revolution |

| G96 | Constant surface speed control |

| G97 | Constant surface speed control cancel |

| G98 | Canned cycle : return to initial level |

| G99 | Canned cycle : return to R point level |

| G107 | Cylindrical interpolation |

| G112 | Polar coordinate interpolation mode |

| G113 | Polar coordinate interpolation mode cancel |

Các sản phẩm phân phối kinh doanh chính :

Với đội ngũ quản lý kỹ sư chuyên nghiệp nhiều kinh nghiệm đông đảo kỹ thuật viên công nhân lành nghề Công ty Cổ Phần Cơ Điện Asia luôn đáp ứng được đa dạng yêu cầu từ Quý khách hàng với chất lượng tốt nhất.

Chúng tôi luôn luôn nỗ lực cải tiến hoàn thiện hệ thống để mang lại cho khách hàng những sản phẩm và dịch vụ tốt nhất, mục tiêu của chúng tôi luôn luôn lấy sự hài lòng của khách hàng làm nền tảng cho sự phát triển bền vững.

Chúng tôi trân trọng cảm ơn Quý khách hàng đã quan tâm và sử dụng sản phẩm dịch vụ của chúng tôi và mong muốn đồng hành cùng sự phát triển của Quý khách hàng

Trân trọng cảm ơn.