Giới thiệu nhà sản xuất Universal Robot

Giới thiệu chung về universal robot

Universal Robot là nhà sản xuất Đan Mạch của các cánh tay robot hợp tác công nghiệp linh hoạt nhỏ hơn, có trụ sở tại Odense, Đan Mạch. Khối lượng kinh doanh năm 2018 là 234 triệu USD. Công ty có hơn 620 nhân viên và 300 đối tác trên khắp thế giới.

Lịch sử Universal Robot

Universal Robots was founded in 2005 by the engineers Esben Østergaard, Kasper Støy, and Kristian Kassow.[2][3] During joint research at the Syddansk Universitet Odense, they came to the conclusion that the robotics market was dominated by heavy, expensive, and unwieldy robots. As a consequence they developed the idea to make robot technology accessible to small and medium-sized businesses.[4] In 2008 the first UR5 cobots were available on the Danish and German market. In 2012 the second cobot, UR10, was launched.[5] At Automatica 2014 in Munich the Company launched a totally revised version of its cobots.[6] One year later, in spring 2015 the table-top cobot UR3 was launched.[7] At Automatica 2018 in Munich a brand new generation of Universal Robots’ cobots called e-Series was launched raising the standard for collaborative robots.

UR was purchased by Teradyne for US$285 million in 2015.[8][9]

Sản phẩm chính của universal Robot

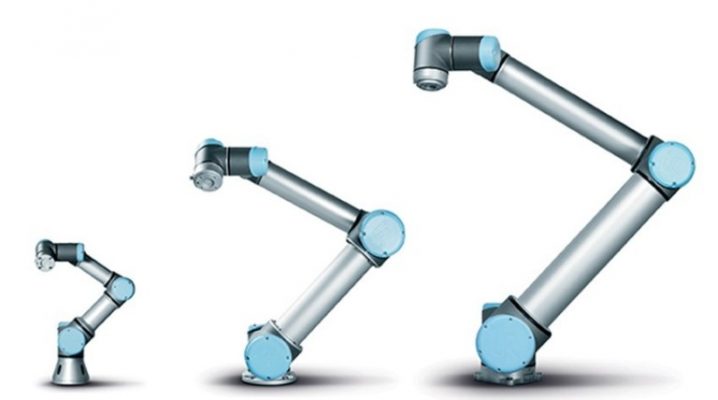

The three main products are the compact table-top cobot UR3,[10] the flexible cobot UR5,[11] and the biggest one, the UR 10.[12] All three are six-jointed robot arms with a very low weight of respectively 11 kilos, 18 kilos and 28 kilos. The UR3 and the UR5 have a lifting ability of 3 and 5 kilos and have a working radius of 500mm and 850mm (19.7 in; 33.5 in). In addition, the UR10 has a lifting ability of 10 kilos with a reach of 1300mm (51.2 in). The accuracy of the cobots’ repetitions is ± 0.1mm (± 0.0039 in). Universal Robots collaborative robots (cobots) can work right alongside personnel with no safety guarding, based on the results of a mandatory risk assessment.[13]

The safety settings of the latest generation of Universal Robots’ lightweight cobots can be adjusted for each specific solution.[14] The robot arm can run in two operating modes of the safety functions; a normal and a reduced one. A switch between safety settings during the cobot’s operation is also possible. All these safety functions are safety rated PL d (EN ISO 13849:2008 ) and certified by TÜV NORD.[15]

Due to their low weight and size, UR’s cobots are mainly used within medium-sized businesses[16] within industries such as packaging, automotive, pharmaceuticals, consumer goods, metal working, and manufacturing.

In 2016, the company launched its online ecosystem Universal Robots+, and in early 2017 it launched a new online digital learning platform called Universal Robots Academy. Through this platform, users go through nine learning modules, learning how to program the UR collaborative robots.

In 2018, a brand new generation of Universal Robots’ cobots called e-Series was launched raising the standard for collaborative robots. The ‘e‘ in e-Series stands for empowering, ease of use, everyone and evolution.[17] The new family has 3 members, like the first CB-series, with an ‘e‘ in the end, the UR3e, UR5e and UR10e. In comparison to the CB Series, they have a higher accuracy for both position repeatability (± 0.03, ± 0.03 and ± 0.05 mm) and force (± 3.5, ± 4.0 and ± 5.5 N) and torque (± 0.10, ± 0.30 and ± 0.60 Nm), since they have a built-in Force/Torque sensor.[18] With the e-Series, they also added a few more safety features, re-designed the Teach Pendant to be more intuitive and simplified the programming flow with more wizards.

Universal Robot