Trung tâm gia công CNC 2 cột kent

Trung tâm gia công cnc kent 2 cột tính năng nổi bật

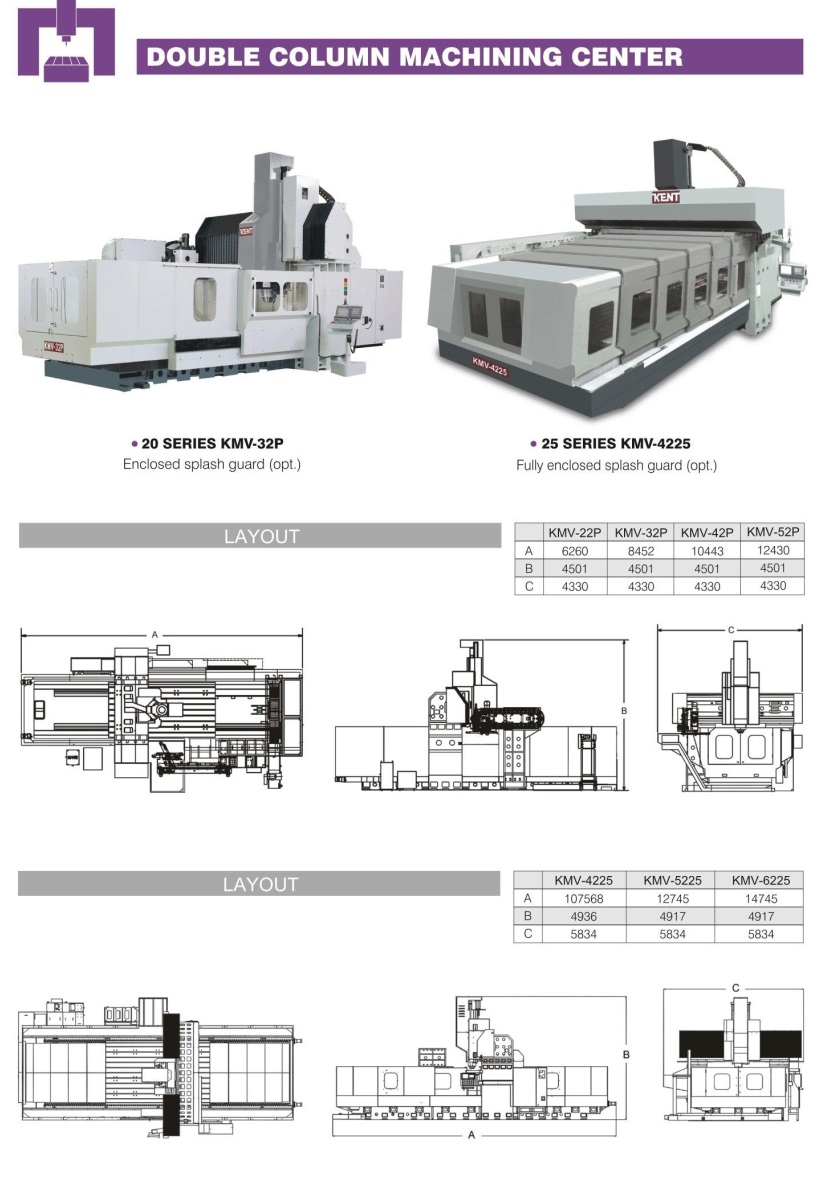

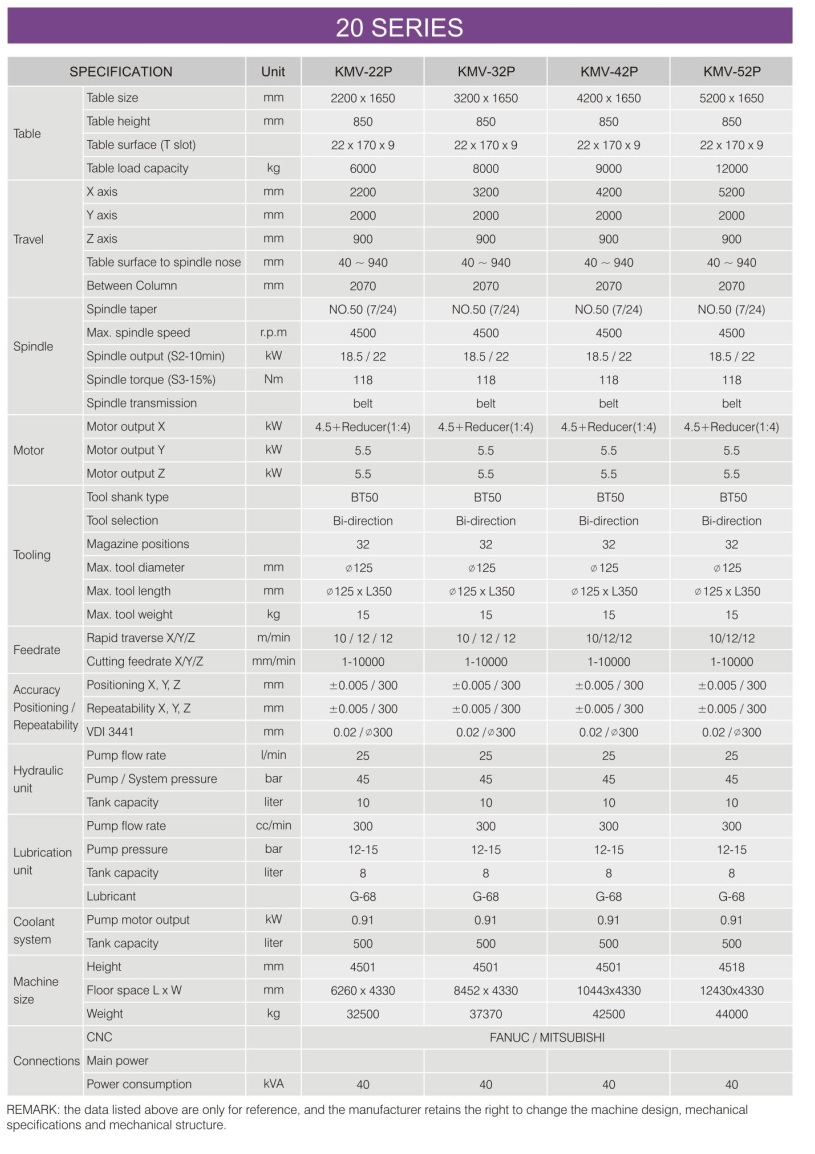

Trung tâm gia công cnc kent 2 cột – dòng 20 series

- Trung tâm gia công KMV 22P

- Trung tâm gia công KMV 32P

- Trung tâm gia công KMV 42P

- Trung tâm gia công KMV 52P

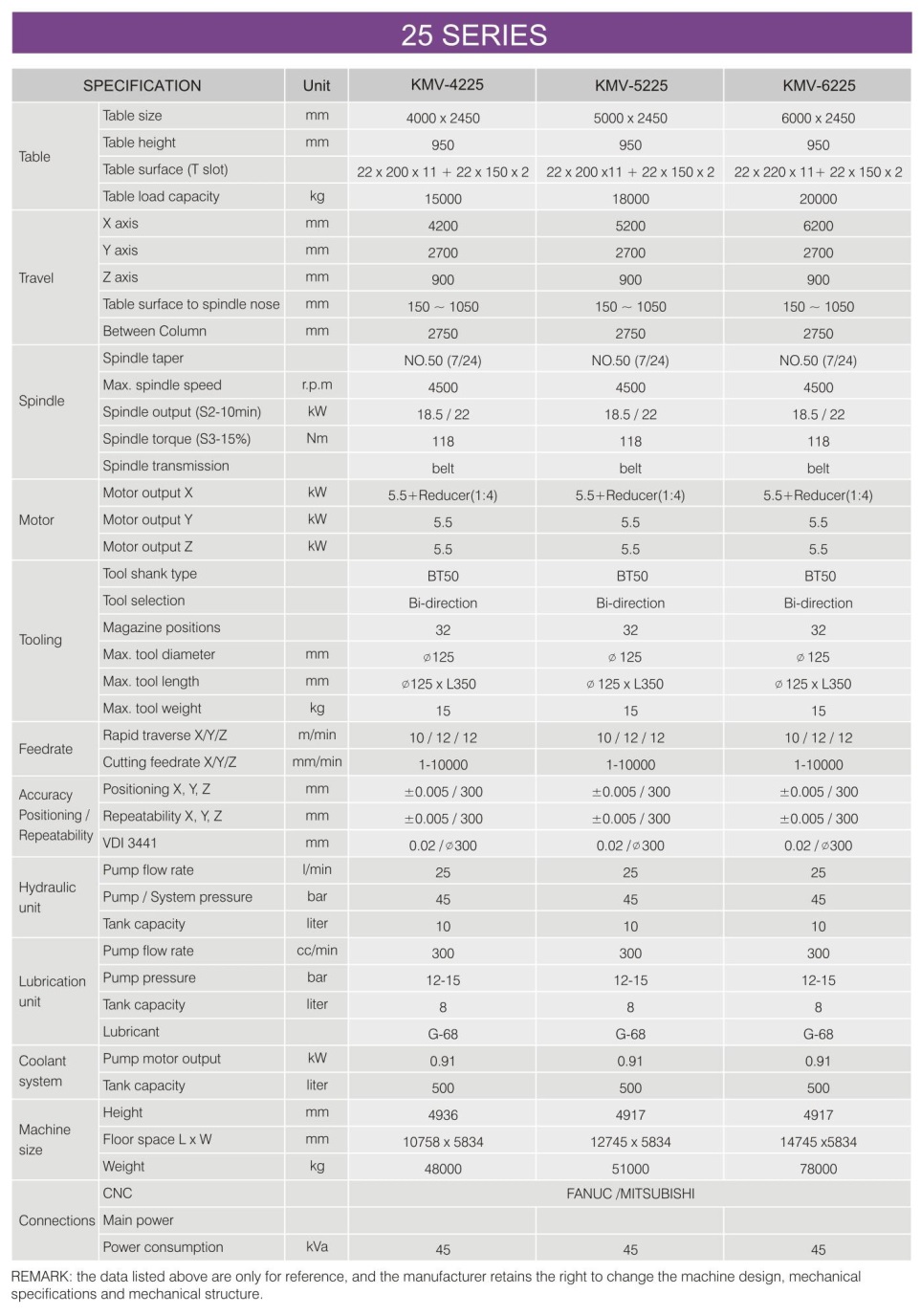

Trung tâm gia công cnc kent 2 cột dòng 25 series

- Trung tâm gia công KMV 4225

- Trung tâm gia công KMV 5225

- Trung tâm gia công KMV 6225

Trung tâm gia công cnc kent 2 cột các tính năng khác

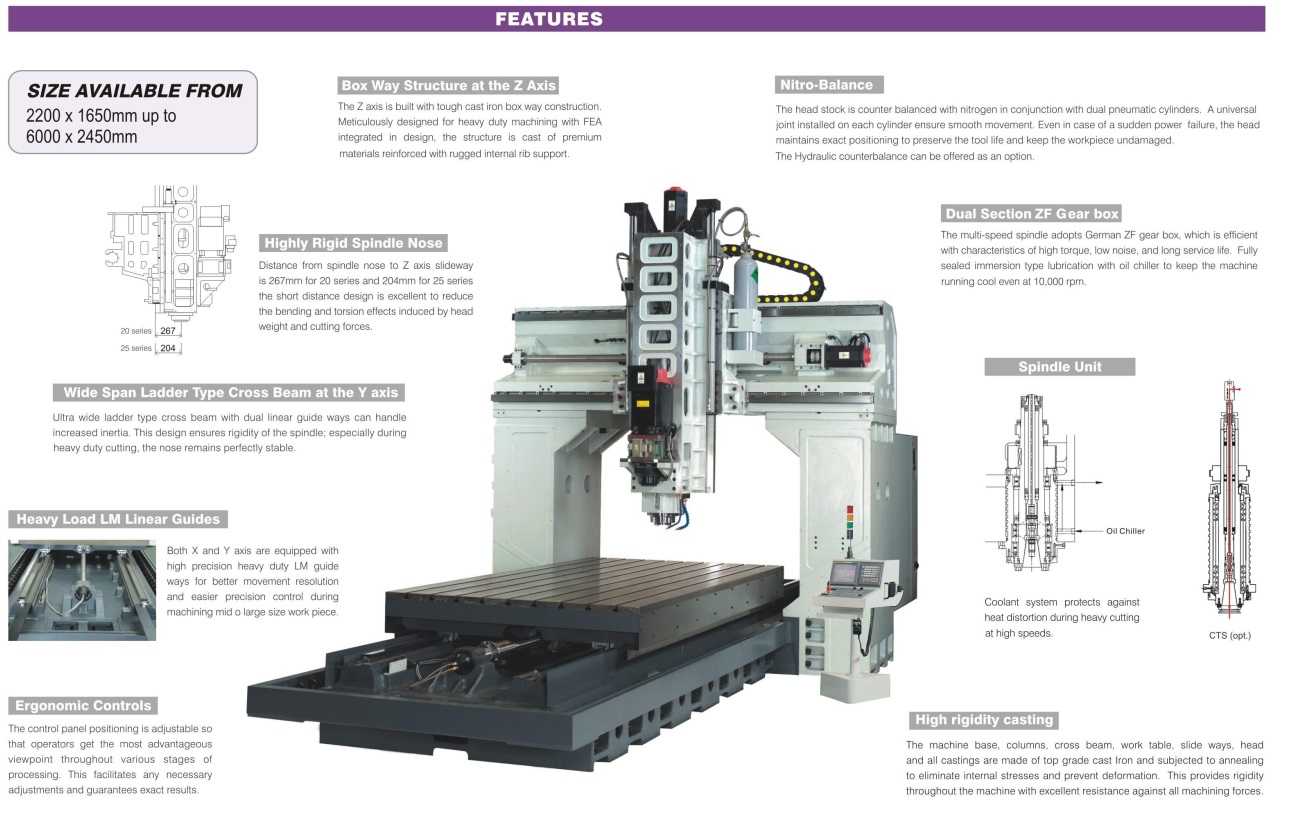

Features:

● The Z axis is built with tough cast iron box construction designed for heavy loads and analyzed for internal stress, also reinforced with rugged internal rib support.

● Ultra wide ladder type cross beam with dual LM linear guide ways ensures rigidity of the spindle and wards off tilting.

● Both X and Y axes are equipped with high precision heavy duty LM guide ways.

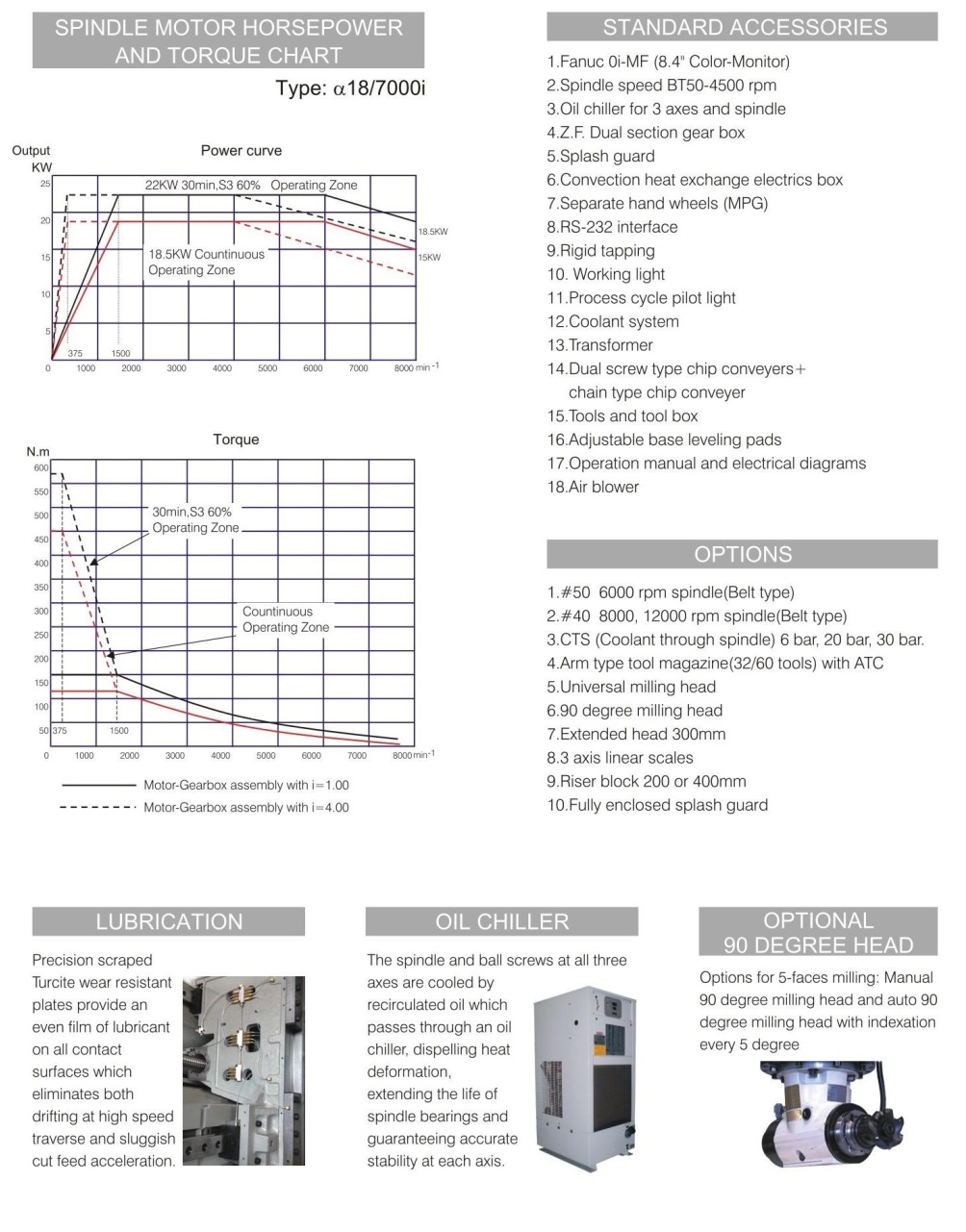

● The standard integrated direct drive spindle employs two pairs of ultra-precision taper roller bearings with oil chiller cooling system. Long nose spindles are available as per customer requirements.

● All three axes adopt pretension super precision hollow core ball screws integrated with a flow- through pressurized coolant system for constant cooling.

● The disc type system is fast and compact. Arm movement is smooth with excellent repeatability. Tool change time is 2.5 seconds (BT40).

● Dual screw type chain driven chip conveyers eliminate debris efficiently.

● Every machine undergoes parameter laser testing and fine tuning before shipment. Each comes with its own certificate of laser testing.

● The Z axis is balanced with Nitrogen in conjunction with dual pneumatic cylinders Nitrogen cushioning of the headstock for automatic balancing during vertical motion.

● The multi-speed spindle is matched with top quality German-built Z.F. dual section gear box. Fully sealed immersion type lubrication with oil chiller circulates coolant and keeps the machine running cool.

● The control panel positioning is adjustable so that operators get the most advantageous viewpoint throughout various stages of processing.

● Sizes available from ( 1800~2500 )mm by ( 2200~6200)mm.

Các sản phẩm phân phối kinh doanh chính :

Chúng tôi trân trọng cảm ơn Quý khách hàng đã quan tâm và sử dụng sản phẩm dịch vụ của chúng tôi và mong muốn đồng hành cùng sự phát triển của Quý khách hàng

Trân trọng cảm ơn.

Increased Profitability

Increase your profitability with Kent CNC’s Vertical Machining Centers—long-lasting units that deliver a precision-grade finish at high speeds.

Our Vertical Machining Center product portfolio offers a wide selection of powerful, rigid machines including compact models, standard #40 and # 50 taper models, models with traveling column or double column designs, and compact 5-axis machining centers with rotary table style or trunnion style designs. With over 18,000 machine tools sold worldwide since 1979, CNC vertical milling centers being one of the biggest portions of it, Kent CNC VMCs are proven to increase productivity, delivering reliable and profitable performance.

Vertical Machining Center Experts

Finding out which vertical machining center is right for your business requires doing your homework first. You may want to ask yourself a few questions.

What types of projects will you be working on? What are your production goals? What types of materials you will be cutting? What are your future plans?

Your VMC mill will need to have the right spindle speed, axis travel, rapids and table size to get the job done.

Trung tâm gia công cnc kent

What shop owners sometimes do is they miscalculate and “over-spec” their machines, spending a ton of money on a CNC vertical machining center that has much more capability than their projects will ever require. On the other hand, others cut themselves short by buying on the cheap and later regretting the fact that their needs require more or that their machine loses accuracy and repeatability.

Both these scenarios affect profitability and defeat the purpose of your investment.

For simpler projects, a 3-axis vertical machining center will hold the workpiece to the table and cut 3-dimensionally on one side. With a 4 or 5-axis rotary, the workpiece can be rotated for machining on a different side or angle and will not require a new set up which is commonly needed for turned parts.

Learn more about the KVR Series VMC with optional rotary table add-on.

Trung tâm gia công cnc kent 2 cột

Đánh giá

Chưa có đánh giá nào.