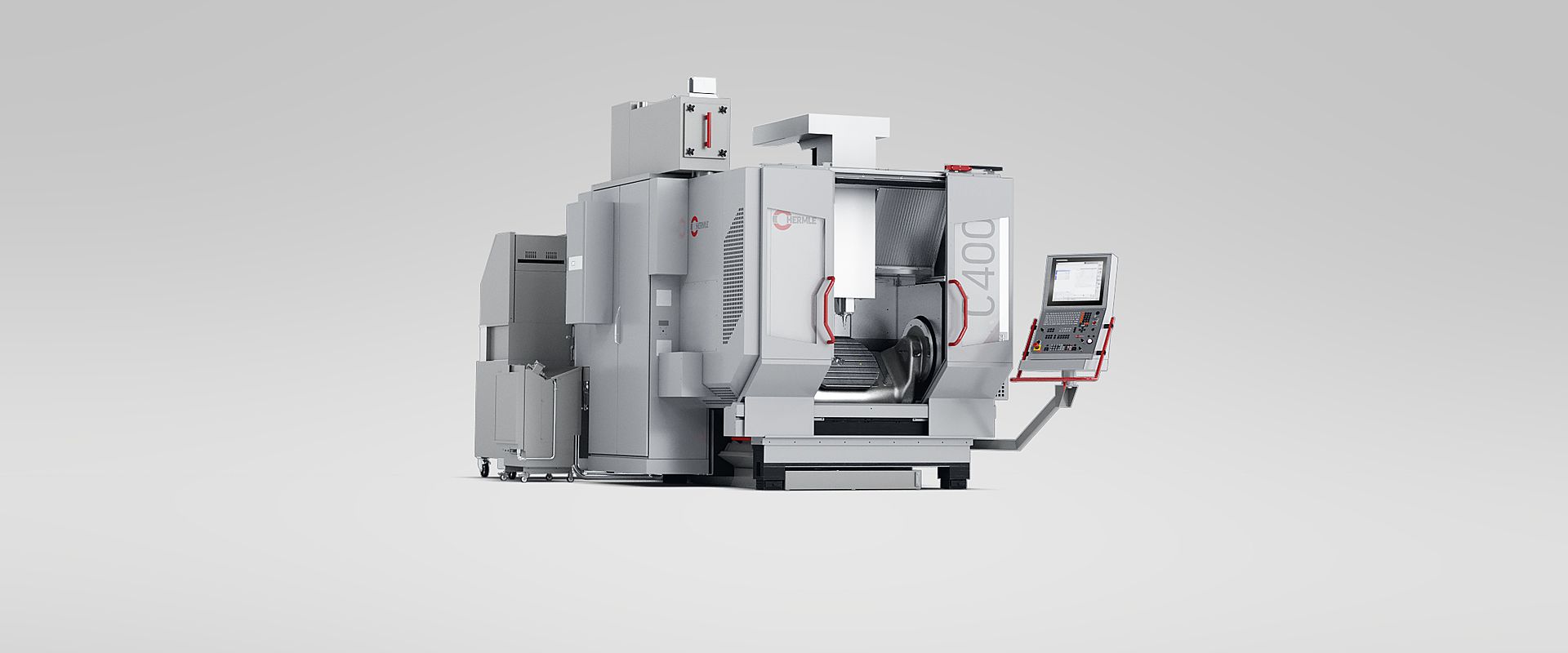

C 400 Machining Centre

C 400 Machining Centre

Many features combine to make for economical 5-axis / 5-side machining. The C 400 machining centre is intended for high performance, large-scale machining of workpieces to high accuracy and surface quality. The C 400 features a large working area with a small installation area and can be ergonomically adapted to every machine operator – thus ensuring optimum ease of use. You can discover more details about the C 400 via the i-buttons in the 360 degree view.

C 400 Machining Centre Specification

Traverse path: 850 x 700 x 500 mm

Body: dia. 650 / H 500

Colision circle: dia.885 mm

Max. vertical table clearance: max. 625 mm

Speed: 15000/18000 1/min

Rapid traverse linear X-Y-Z:m/min

Rigid clamping table:1070 x 700 mm

max. table load: 2000 kg

HIGH-TECH TOOL SPINDLES WITH COLLISION PROTECTION

Like the swivelling rotary tables, the tool spindles are also completely manufactured in-house at the Gosheim site. The slimline tool spindles are constructed in two parts and can be replaced easily and quickly during servicing. Thanks to low interfering edges and collision protection by compression sleeves, safety is given primary importance by maximum collision avoidance. Damage can be prevented in 50 % of collisions.

IN MANUFACTURING AND OPERATION

Hermle manufactures many components using lightweight construction and mineral casting technology. The high degree of own production, local suppliers and components with high efficiency factors also promote energy efficiency. Energy recuperation, high-quality servo drives and the legendary long service lives are all proof of the same high standards during actual operation.

HEIDENHAIN TNC 640

The control unit provides for free contour programming and functions for fast 3D work as well as a trackball, USB and Ethernet interfaces. Options such as Dynamic Efficiency, Dynamic Precision or the Kinematic Opt. software also serve to widen the range of functions. Exact setup and control elements from Hermle simplify and improve operation.

WITH TOOL CHANGER

The pick-up tool magazine of the C 400 is integrated into the machine bed, making for very good accessibility. There are 38 magazine pockets available, with a maximum tool weight of 8 kg and a maximum tool length of 300 mm. As an option, the capacity can be increased through the ZM 50 and ZM 88 additional magazines.

FLEXIBLE MACHINE STATE MONITORING

The HIMS control tool (‘Hermle Information Management System’) allows for flexible machine state monitoring for the C 400, including a ‘Live Messenger’ amongst other features. The Hermle High-Performance Line models can also be automated to a considerably greater degree, including the addition of pallet changers, handling, rotary loading and robot systems and pneumatic arbour holders.

EVERYTHING WELL THOUGHT-THROUGH

From the comprehensive fluid technology to the optimized chip management system and a range of cooling lubricant units to the hinged belt conveyor: The Performance Line model C 400 has a number of highlights to offer, e.g. the right chip disposal equipment for removing all types of chip from the working area. This machining centre for 5-axis /5-sided machining can be transported without being dismantled and set up without a foundation.

Công ty Cổ Phần Cơ Điện Asia (ASIAME JSC) chuyên cung cấp sản phẩm và dịch vụ liên quan tới ngành cơ điện tự động hóa

Các sản phẩm phân phối kinh doanh chính :

Robot công nghiệp Yaskawa Nhật Bản

Biến tần một chiều- DC driver- Sprint Electric- Italia

Máy biến áp FUJI- Nhật Bản

Động cơ thường và động cơ hộp số Mitsubishi- Nhật Bản

Hóa chất giảm điện trở đất, sử dụng trong các hệ thống tiếp địa.

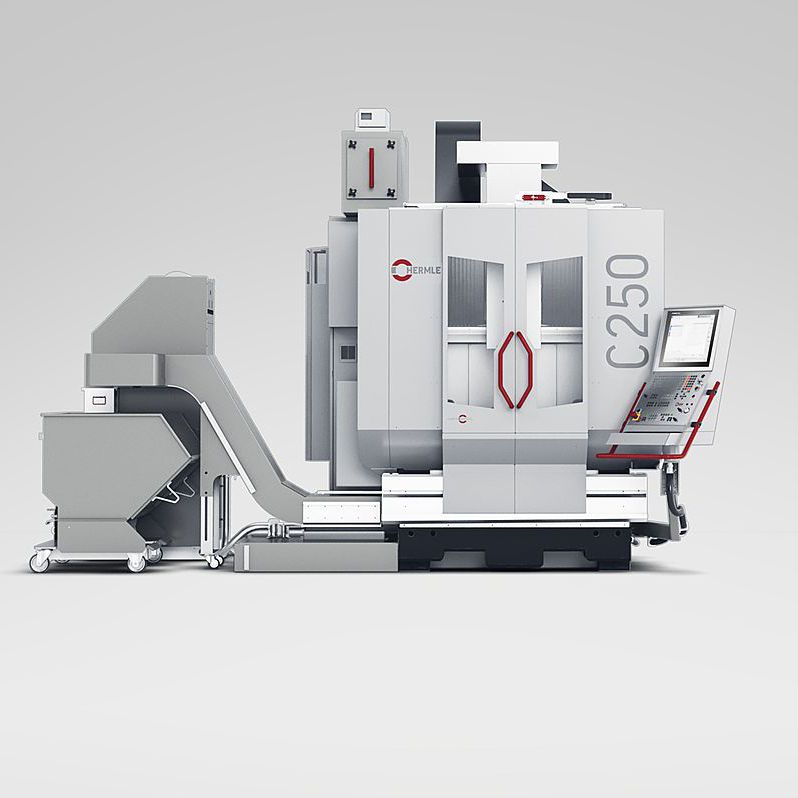

Tham khảo thêm máy công cụ

Với đội ngũ quản lý kỹ sư chuyên nghiệp nhiều kinh nghiệm đông đảo kỹ thuật viên công nhân lành nghề Công ty Cổ Phần Cơ Điện Asia luôn đáp ứng được đa dạng yêu cầu từ Quý khách hàng với chất lượng tốt nhất.

Đánh giá

Chưa có đánh giá nào.