Trung tâm gia công CNC DMG DMU 200 Gantry

Catalog download

DMU 200 Gantry

Flexibility through spindle versions

- Vertical spindle with 20,000 rpm

- 45° head and 90° head for 5-axes machining up to 30,000 rpm

- Ready for new technologies like Ultrasonic, Laser or machining of carbon material

Working area concept

- Fixed table 2,250 x 2,000 mm with 10,000 kg loading capacity

- T-slots across the table for easy chip removal

- Chip conveyors on both sides of the table

Low Gantry Design

- 50 m/min rapid traverse

- Best visibility into the working area through missing side walls

- Maximum utilisation of the working area

5-axes machining

- 45° head with 90° swivel range and +/- 300° rotating range

- compactMASTER spindle with 20,000 rpm

- 90° head with +/- 120° swivel range and +/- 300° rotating range

- compactMASTER spindel with 20,000 rpm up to 30,000 rpm

DMU 200 Gantry Specification

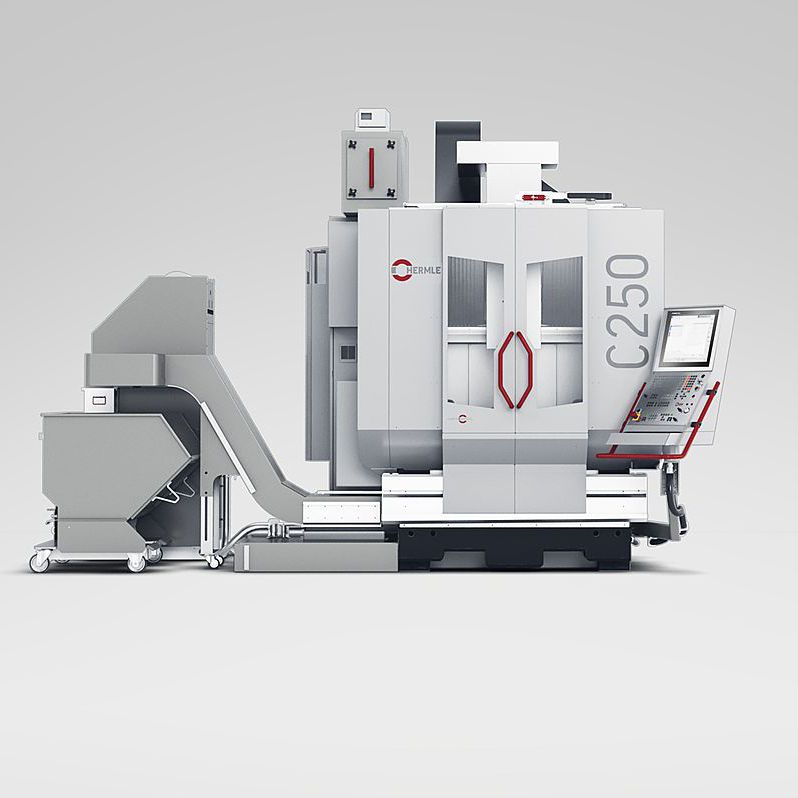

Dynamic Gantry design machine for the machining of large workpieces

The DMU 200 Gantry from DMG MORI

5-axis machining with up to 30 000rpm and optional technology integration. 0.5 g acceleration for highly dynamic machining of large components up to 10 000kg on less than 24m² footprint.

The DMU 200 Gantry from DMG MORI impressively combines the machining of large components and maximum dynamics. Users benefit in the aerospace and automotive industry as well as in model making and the energy sector.

With the 5-axis machining of up to 30 000rpm and optional Ultrasonic or Lasertec technology integration, more complex components weighing up to 10 000kg made of aluminium or composites as well as welded components can be machined economically. The machine can be easily loaded from the top with a crane. The low gantry design of the DMU 200 Gantry enables optimum utilisation of the work area. With a footprint of no more than 4 300 by 5 400mm, the machine achieves travel paths of 2 000 x 2 000 x 1 200mm, with which DMG MORI is successfully complementing its product range between the DMF and the DMU P series.

The combination of cast iron machine bed and gantry portal creates a solid basis for the high dynamics. With rapid traverses of up to 50m/min and 0.5 g acceleration, large components can be machined efficiently. Depending on the field of application, two milling heads are available for 5-axis simultaneous machining, a 45° as well as a 90° milling head. The first one enables the best possible utilisation of the work area, while the 90° milling head enables the use of application-specific spindles, including the compactMASTER with a rotational speed of 20 000rpm as standard in the 5-axis version. Additional spindle options comprise rotational speeds of 24 000rpm, 28 000rpm and 30 000rpm. The vertical 3-axis version of the DMU 200 Gantry is equipped ex works with a speedMASTER spindle with 20 000rpm. Adding to this is the optional Ultrasonic milling head as well as the Lasertec Shape Technology. This technology can be used to completely machine moulded parts including surface structuring.

For the machining of composites or modelling material like Ureol, a highly efficient tripartite dust extraction is optionally available. This consists of an extraction system on the spindle nose, an extraction system in the table area and a work area extraction system with continuous volumetric flow. The basic construction of the machine was already designed with this in mind.

The DMG MORI toolSTAR tool magazine has 30 pockets as standard. Optionally, up to 120 tool stations are possible. The DMU 200 Gantry is perfectly accessible from two sides. The DMG MORI ERGOline terminal with 21.5” multi-touch screen and Celos can be easily swivelled to both sides.

Đánh giá

Chưa có đánh giá nào.