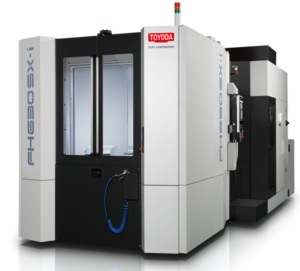

Toyoda’s Multitasking Horizontal Machining Center GS200H

Toyoda’s Multitasking Horizontal Machining Center is the first in the world to equip a skiving function to a general purpose horizontal type machining center to achieve mass production of gear parts. The GS200H offers improved productivity and flexible machining through high speed cutting and integrated gear part processes of lathe, gear skiving and machining center capabilities. Offering continuous machining on the shop floor, the GS200H ultimately reduces equipment and cutting tools utilized.

GS200H Specification

| X-Axis Travel | 18.5″ (470 mm) |

| Y-Axis Travel | 14.2″ (360 mm) |

| Z-Axis Travel | 24.2″ (620 mm) |

| B-axis Rotating Range(table) | 220° (0 ~ -220°), 0.001° |

| Rapid Feedrate | 1,889 ipm (48 m/min) |

| Spindle Nose Shape | BT No.50 |

| Spindle Speed | 6,000 min-1 |

| Spindle Drive Motor (30 min. / cont.) | 40 HP (30 kW) / 33 HP (25 kW) |

| Rotating Speed | 3,000 min-1 |

| Rated Output | 43 HP (32 kW) / 26 HP (19.5 kW) [Optional: 45 HP (33.5 kW) / 38 HP (28.3 kW) |

| Torque max. / cont. | 95.1 ft-lb (129 Nm) / 45.7 ft-lb (62 Nm) |

| Max Workpiece Swing | ⌀20.7″ (⌀528 mm) |

| Length | 7.87″ (200 mm) or less |

| Max Workpiece Diameter | ⌀8.7″ (⌀220 mm) |

| Tool Storage Capacity | 8 Standard (20 Optional) |

| Standard Floor Space | 94.5″ x 118″ (2,400 mm x 3,000 mm) |

| Machine Height | 123″ (3,112 mm) |

| Standard Net Weight | 28,600 lb (13,000 kg) |

Đánh giá

Chưa có đánh giá nào.