Lỗi máy CNC Haas

Lỗi máy CNC Haas Haas Alarm Codes

- 101 – COMM. FAILURE WITH MOCON/MOCON MEMORY FAULT

- 102 – SERVOS OFF

- 103 – X SERVO ERROR TOO LARGE

- 104 – Y SERVO ERROR TOO LARGE

- 105 – Z SERVO ERROR TOO LARGE

- 106 – A SERVO ERROR TOO LARGE

- 107 – EMERGENCY OFF

- 108 – X SERVO OVERLOAD

- 109 – Y SERVO OVERLOAD

- 110 – Z SERVO OVERLOAD

- 111 – A SERVO OVERLOAD

- 112 – NO INTERRUPT

- 113 – TURRET UNLOCK FAULT – Haas Lathe

- 113 – SHUTTLE IN FAULT – Haas Mill

- 114 – TURRET LOCK FAULT – Haas Lathe

- 114 – SHUTTLE OUT FAULT – Haas Mill

- 115 – TURRET ROTATE FAULT – Haas Lathe

- 115 – TURRET ROTATE FAULT – Haas Mill

- 116 – SPINDLE ORIENTATION FAULT

- 117 – SPINDLE HIGH GEAR FAULT

- 118 – SPINDLE LOW GEAR FAULT

- 119 – OVERVOLTAGE

- 120 – LOW AIR PRESSURE

- 121 – LOW LUBE OR LOW PRESSURE

- 122 – REGEN OVERHEAT

- 123 – SPINDLE DRIVE FAULT

- 124 – LOW BATTERY

- 125 – TOOL TURRET FAULT – Haas Lathe

- 125 – SHUTTLE FAULT – Haas Mill

- 126 – GEAR FAULT

- 127 – DOOR FAULT – Haas Lathe

- 127 – NO TURRET MARK – Haas Mill

- 128 – SUPER TRAVEL ENABLED ON MULTIPLE AXES – Haas Mill

- 129 – M FIN FAULT

- 130 – CHUCK UNCLAMPED – Haas Lathe

- 130 – TOOL UNCLAMPED – Haas Mill

- 131 – TOOL NOT CLAMPED – Haas Mill

- 132 – POWER DOWN FAILURE

- 133 – SPINDLE BRAKE ENGAGED – Haas Lathe

- 133 – SPINDLE INOPERATIVE – Haas Mill

- 134 – LOW HYDRAULIC PRESSURE – Haas Lathe

- 134 – TOOL CLAMP FAULT – Haas Mill

- 135 – X-AXIS MOTOR OVERHEAT

- 136 – Y-AXIS MOTOR OVERHEAT

- 137 – Z-AXIS MOTOR OVERHEAT

- 138 – A-AXIS MOTOR OVERHEAT

- 139 – X-AXIS MOTOR Z FAULT

- 140 – Y-AXIS MOTOR Z FAULT

- 141 – Z-AXIS MOTOR Z FAULT

- 142 – A-AXIS MOTOR Z FAULT

- 143 – SPINDLE ORIENTATION LOST – Haas Lathe

- 143 – SPINDLE ORIENTATION LOST – Haas Mill

- 144 – TIMEOUT – CALL YOUR DEALER

- 145 – X LIMIT SWITCH

- 146 – Y LIMIT SWITCH

- 147 – Z LIMIT SWITCH

- 148 – A LIMIT SWITCH

- 149 – SPINDLE TURNING – Haas Lathe

- 149 – SPINDLE TURNING – Haas Mill

- 150 – I_MODE OUT OF RANGE – Haas Lathe

- 150 – Z AND TOOL INTERLOCKED – Haas Mill

- 151 – HPC LOW PRESSURE – Haas Lathe

- 151 – LOW THRU SPINDLE COOLANT – Haas Mill

- 152 – SELF TEST FAIL

- 153 – X AXIS Z CH MISSING

- 154 – Y AXIS Z CH MISSING

- 155 – Z AXIS Z CH MISSING

- 156 – A AXIS Z CH MISSING

- 157 – MOCON WATCHDOG FAULT

- 158 – VIDEO/KEYBOARD PCB FAILURE

- 159 – KEYBOARD FAILURE

- 160 – LOW VOLTAGE – Haas Lathe

- 160 – LOW VOLTAGE – Haas Mill

- 161 – X AXIS DRIVE FAULT

- 162 – Y AXIS DRIVE FAULT

- 163 – Z AXIS DRIVE FAULT

- 164 – A AXIS DRIVE FAULT

- 165 – X ZERO RET MARGIN TOO SMALL

- 166 – Y ZERO RET MARGIN TOO SMALL

- 167 – Z ZERO RET MARGIN TOO SMALL

- 168 – A ZERO RET MARGIN TOO SMALL

- 169 – SPINDLE DIRECTION FAULT

- 170 – ENABLED AXIS NEEDS MOCON2 – Haas Mill

- 171 – rpm TOO HIGH TO UNCLAMP – Haas Lathe

- 171 – APC-PALLET CLAMP TIMEOUT – Haas Mill

- 172 – DOOR IS OPEN AND SPINDLE IS TURNING – Haas Lathe

- 172 – APC-PALLET UNCLAMP TIMEOUT – Haas Mill

- 173 – SPINDLE ENCODER Z CH MISSING

- 174 – TOOL LOAD EXCEEDED – Haas Lathe

- 174 – TOOL LOAD EXCEEDED – Haas Mill

- 175 – GROUND FAULT DETECTED

- 176 – OVERHEAT SHUTDOWN

- 177 – OVERVOLTAGE SHUTDOWN

- 178 – DIVIDE BY ZERO

- 179 – LOW PRESSURE TRANS OIL

- 180 – PALLET/FIXTURE NOT CLAMPED – Haas Mill

- 181 – MACRO NOT COMPLETED – SPINDLE DISABLED

- 182 – X CABLE FAULT

- 183 – LIVE TOOLING CABLE FAULT – Haas Lathe

- 183 – Y CABLE FAULT – Haas Mill

- 184 – Z CABLE FAULT

- 185 – A CABLE FAULT

- 186 – SPINDLE NOT TURNING

- 187 – B SERVO ERROR TOO LARGE – Haas Lathe

- 187 – B SERVO ERROR TOO LARGE – Haas Mill

- 188 – B SERVO OVERLOAD

- 189 – B-AXIS MOTOR OVERHEAT

- 190 – B MOTOR Z FAULT

- 191 – B LIMIT SWITCH

- 192 – B AXIS Z CH MISSING

- 193 – B AXIS DRIVE FAULT

- 194 – B ZERO RET MARGIN TOO SMALL

- 195 – B CABLE FAULT

- 196 – COOLANT SPIGOT FAILURE – Haas Mill

- 197 – MISC. SOFTWARE ERROR

- 198 – SPINDLE STALLED

- 199 – NEGATIVE rpm

- 200 – VD OVER TEMP.

- 201 – PARAMETER CRC ERROR

- 202 – SETTING CRC ERROR

- 203 – LEAD SCREW CRC ERROR

- 204 – OFFSET CRC ERROR

- 205 – PROGRAMS CRC ERROR

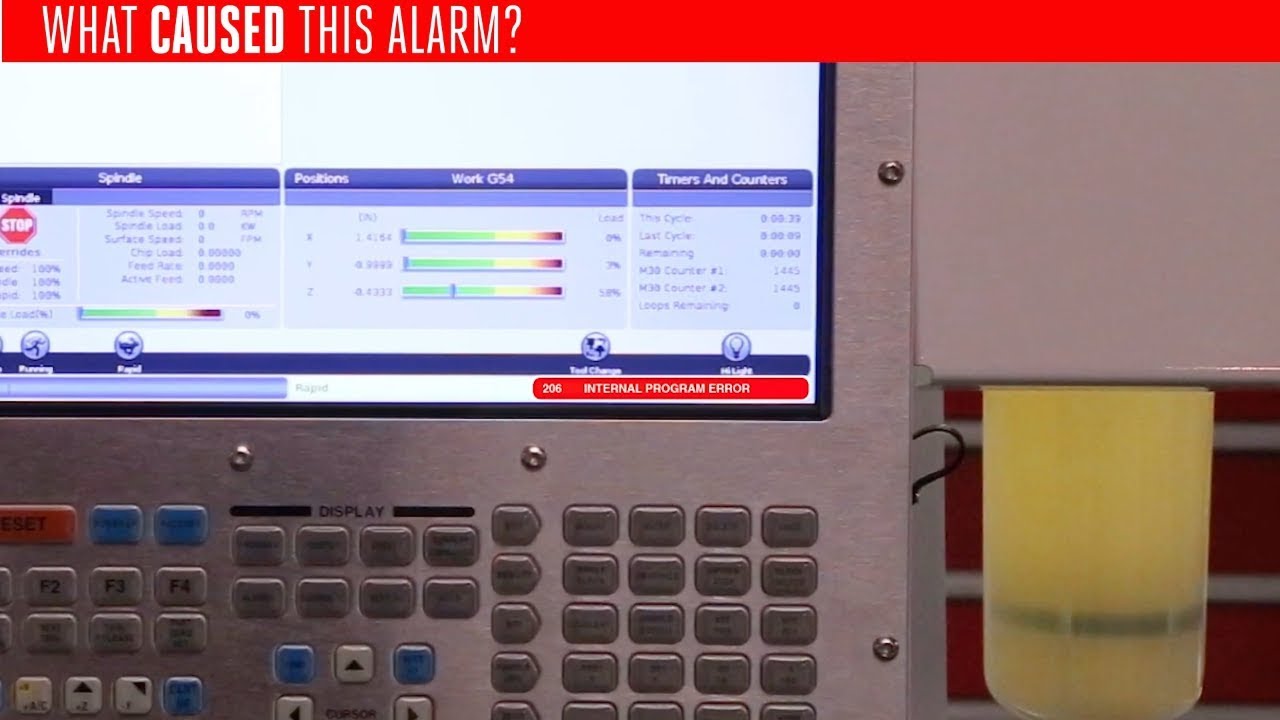

- 206 – INTERNAL PROG ERROR

- 207 – QUEUE ADVANCE ERROR

- 208 – QUEUE ALLOCATION ERROR

- 209 – QUEUE CUTTER COMP ERROR

- 210 – INSUFFICIENT MEMORY

- 211 – ODD PROG BLOCK

- 212 – PROG INTEGRITY ERROR

- 213 – PROGRAM RAM CRC ERROR

- 214 – NO. OF PROGRAMS CHANGED

- 215 – FREE MEMORY PTR CHANGED

- 216 – PROBE ARM DOWN WHILE RUNNING – Haas Lathe

- 216 – EPROM SPEED FAILURE – Haas Mill

- 217 – X PHASING ERROR

- 218 – Y PHASING ERROR

- 219 – Z PHASING ERROR

- 220 – A PHASING ERROR

- 221 – B PHASING ERROR

- 222 – C PHASING ERROR

- 223 – DOOR LOCK FAILURE

- 224 – X TRANSITION FAULT

- 225 – Y TRANSITION FAULT

- 226 – Z TRANSITION FAULT

- 227 – A TRANSITION FAULT

- 228 – B TRANSITION FAULT

- 229 – C TRANSITION FAULT

- 230 – DOOR OPEN – Haas Lathe

- 231 – JOG HANDLE TRANSITION FAULT

- 232 – SPINDLE TRANSITION FAULT

- 233 – JOG HANDLE CABLE FAULT

- 234 – SPINDLE CABLE FAULT

- 235 – SPINDLE Z FAULT

- 236 – SPINDLE MOTOR OVERLOAD

- 237 – SPINDLE FOLLOWING ERROR

- 238 – AUTOMATIC DOOR FAULT – Haas Mill

- 239 – UNKNOWN MOCON1 ALARM

- 240 – EMPTY PROG OR NO EOB

- 241 – INVALID CODE

- 242 – NUMBER FORMAT ERROR-OR TOO LONG

- 243 – BAD NUMBER

- 244 – MISSING (…)

- 245 – UNKNOWN CODE

- 246 – STRING TOO LONG

- 247 – CURSOR DATA BASE ERROR

- 248 – NUMBER RANGE ERROR

- 249 – PROG DATA BEGINS ODD

- 250 – PROG DATA ERROR

- 251 – PROG DATA STRUCT ERROR

- 252 – MEMORY OVERFLOW

- 253 – ELECTRONICS OVERHEAT

- 254 – SPINDLE MOTOR OVERHEAT

- 255 – NO TOOL IN SPINDLE – Haas Mill

- 256 – CURRENT TOOL UNKNOWN – Haas Mill

- 257 – PROG DATA ERROR

- 258 – INVALID DPRNT FORMAT

- 259 – LANGUAGE VERSION

- 260 – LANGUAGE CRC

- 261 – ROTARY CRC ERROR

- 262 – PARAMETER CRC MISSING

- 263 – LEAD SCREW CRC MISSING

- 264 – ROTARY CRC MISSING

- 265 – MACRO VARIABLE FILE CRC ERROR

- 266 – TOOL CHANGER FAULT – Haas Mill

- 267 – TOOL DOOR OUT OF POSITION – Haas Mill

- 268 – DOOR OPEN @ M95 START

- 269 – TOOL ARM FAULT – Haas Mill

- 270 – C SERVO ERROR TOO LARGE

- 271 – C SERVO OVERLOAD

- 272 – C-AXIS MOTOR OVERHEAT

- 273 – C MOTOR Z FAULT

- 274 – C LIMIT SWITCH

- 275 – C AXIS Z CH MISSING

- 276 – C AXIS DRIVE FAULT

- 277 – C ZERO RET MARGIN TOO SMALL

- 278 – C CABLE FAULT

- 279 – X AXIS LINEAR SCALE Z FAULT – Haas Mill

- 280 – Y AXIS LINEAR SCALE Z FAULT – Haas Mill

- 281 – Z AXIS LINEAR SCALE Z FAULT – Haas Mill

- 282 – A AXIS LINEAR SCALE Z FAULT – Haas Mill

- 283 – X AXIS LINEAR SCALE Z CH MISSING – Haas Mill

- 284 – Y AXIS LINEAR SCALE Z CH MISSING – Haas Mill

- 285 – Z AXIS LINEAR SCALE Z CH MISSING – Haas Mill

- 286 – A AXIS LINEAR SCALE Z CH MISSING – Haas Mill

- 287 – X AXIS LINEAR SCALE CABLE FAULT – Haas Mill

- 288 – Y AXIS LINEAR SCALE CABLE FAULT – Haas Mill

- 289 – Z AXIS LINEAR SCALE CABLE FAULT – Haas Mill

- 290 – A AXIS LINEAR SCALE CABLE FAULT – Haas Mill

- 291 – LOW AIR VOLUME/PRESSURE DURING ATC – Haas Mill

- 292 – 320V VD/MMPS FAULT

- 293 – INVALID CHAMFER OR CORNER ROUNDING DISTANCE IN G01

- 294 – NO END MOVE FOR G01 CHAMFER CORNER ROUNDING

- 295 – MOVE ANGLE TOO SMALL IN G01 CORNER ROUNDING

- 296 – INVALID PLANE SELECTION IN G01 CHAMFER OR CORNER ROUNDING

- 297 – ATC SHUTTLE OVERSHOOT – Haas Mill

- 298 – ATC DOUBLE ARM OUT OF POSITION – Haas Mill

- 299 – ATC SHUTTLE OUT OF POSITION – Haas Mill

- 301 – NORMAL STOP – Haas Lathe

- 302 – INVALID R IN G02 OR G03

- 303 – INVALID X,B OR Z IN G02 OR G03 – Haas Lathe

- 303 – INVALID X, Y OR Z IN G02 OR G03 – Haas Mill

- 304 – INVALID I,J OR K IN G02 OR G03

- 305 – INVALID Q IN CANNED CYCLE

- 306 – INVALID I,J,K, OR Q IN CANNED CYCLE

- 307 – SUBROUTINE NESTING TOO DEEP

- 308 – INVALID TOOL OFFSET – Haas Lathe

- 309 – EXCEEDED MAX FEEDRATE

- 310 – INVALID G CODE

- 311 – UNKNOWN CODE

- 312 – PROGRAM END

- 313 – NO P CODE IN M96, M97, M98, M143, M144, or G65

- 314 – SUBPROGRAM NOT IN MEMORY

- 315 – INVALID P CODE IN M97, M98 OR M99 – Haas Lathe

- 315 – INVALID P CODE IN M98, M97, M96, G47 OR G65 – Haas Mill

- 316 – X OVER TRAVEL RANGE

- 317 – Y OVER TRAVEL RANGE – Haas Lathe

- 317 – Y OVER TRAVEL RANGE – Haas Mill

- 318 – Z OVER TRAVEL RANGE

- 319 – A OVER TRAVEL RANGE

- 320 – NO FEED RATE

- 321 – AUTO OFF ALARM

- 322 – SUB PROG WITHOUT M99

- 323 – ATM CRC ERROR – Haas Mill

- 324 – DELAY TIME RANGE ERROR

- 325 – QUEUE FULL

- 326 – G04 WITHOUT P CODE

- 327 – NO LOOP FOR M CODE EXCEPT M97, 98

- 328 – INVALID TOOL NUMBER

- 329 – UNDEFINED M CODE

- 330 – UNDEFINED MACRO CALL

- 331 – RANGE ERROR

- 332 – H AND T NOT MATCHED – Haas Mill

- 333 – X AXIS DISABLED

- 334 – Y AXIS DISABLED – Haas Lathe

- 334 – Y AXIS DISABLED – Haas Mill

- 335 – Z AXIS DISABLED

- 336 – A AXIS DISABLED – Haas Lathe

- 336 – A AXIS DISABLED – Haas Mill

- 337 – GOTO OR P LINE NOT FOUND

- 338 – INVALID IJK AND XYZ IN G02 OR G03

- 339 – MULTIPLE CODES

- 340 – CUTTER COMP BEGIN WITH G02 OR G03

- 341 – CUTTER COMP END WITH G02 OR G03

- 342 – CUTTER COMP PATH TOO SMALL

- 343 – DISPLAY QUEUE RECORD FULL

- 344 – CUTTER COMP WITH G17 & G19 – Haas Lathe

- 344 – CUTTER COMP WITH G18 & G19 – Haas Mill

- 345 – INVALID R VALUE IN M19 OR G105 – Haas Lathe

- 346 – M CODE DISABLED – Haas Lathe

- 346 – M CODE DISABLED A – Haas Mill

- 348 – ILLEGAL SPIRAL MOTION – Haas Lathe

- 348 – MOTION NOT ALLOWED IN G93 MODE – Haas Mill

- 349 – PROG STOP WITHOUT CANCELING CUTTER COMP

- 350 – CUTTER COMP LOOK AHEAD ERROR

- 351 – INVALID P CODE

- 352 – AUX AXIS POWER OFF

- 353 – AUX AXIS NO HOME – Haas Lathe

- 353 – AUX AXIS NO HOME – Haas Mill

- 354 – AUX AXIS DISCONNECTED

- 355 – AUX AXIS POSITION MISMATCH

- 356 – AUX AXIS TRAVEL LIMIT

- 357 – AUX AXIS DISABLED

- 358 – MULTIPLE AUX AXIS

- 359 – INVALID I, J OR K IN G12 OR G13 – Haas Mill

- 360 – TOOL CHANGER DISABLED

- 361 – GEAR CHANGER DISABLED

- 362 – TOOL USAGE ALARM

- 363 – COOLANT LOCKED OFF

- 364 – NO CIRC INTERP AUX AXIS

- 365 – P DEFINITION ERROR

- 366 – MISSING I, K, OR L IN G70, G71, G72 – Haas Mill

- 367 – CUTTER COMP INTERFERENCE

- 368 – GROOVE TOO SMALL

- 369 – TOOL TOO BIG

- 370 – TAILSTOCK EXCESSIVE DRIFT – Haas Lathe

- 370 – POCKET DEFINITION ERROR – Haas Mill

- 371 – INVALID I, J, K OR Q

- 372 – TOOL CHANGE IN CANNED CYCLE

- 373 – INVALID CODE IN DNC

- 374 – MISSING XBZA IN G31 OR G36 – Haas Lathe

- 374 – MISSING XYZA IN G31 OR G36 – Haas Mill

- 375 – MISSING Z OR H IN G37 – Haas Mill

- 376 – NO CUTTER COMP IN SKIP

- 377 – NO SKIP IN GRAPH/SIM

- 378 – SKIP SIGNAL FOUND

- 379 – SKIP SIGNAL NOT FOUND

- 380 – X, Y, A OR G49 NOT ALLOWED IN G37

- 381 – G43,G44 NOT ALLOWED IN G36 OR G136

- 382 – D CODE REQUIRED IN G35

- 383 – INCH IS NOT SELECTED

- 384 – METRIC IS NOT SELECTED

- 385 – INVALID L, P, OR R CODE IN G10

- 386 – INVALID ADDRESS FORMAT

- 387 – CUTTER COMP NOT ALLOWED WITH G103

- 388 – CUTTER COMP NOT ALLOWED WITH G10

- 389 – G17, G18, G19 ILLEGAL IN G68

- 390 – NO SPINDLE SPEED

- 391 – FEATURE DISABLED

- 392 – B AXIS DISABLED – Haas Lathe

- 392 – B AXIS DISABLED – Haas Mill

- 393 – INVALID MOTION IN G84 OR G184 – Haas Lathe

- 393 – INVALID MOTION IN G74 OR G84 – Haas Mill

- 394 – B OVER TRAVEL RANGE – Haas Lathe

- 394 – B OVER TRAVEL RANGE – Haas Mill

- 395 – INVALID CODE IN CANNED CYCLE – Haas Lathe

- 395 – NO G107 ROTARY AXIS SPECIFIED – Haas Mill

- 396 – CONFLICTING AXES – Haas Lathe

- 396 – INVALID G107 ROTARY AXIS SPECIFIED – Haas Mill

- 397 – INVALID D CODE – Haas Lathe

- 397 – AUX AXIS IN G93 BLOCK – Haas Mill

- 398 – AUX AXIS SERVO OFF

- 399 – INVALID U CODE – Haas Lathe

- 400 – SKIP SIGNAL DURING RESTART

- 401 – INVALID TANGENT IN GROUP 1 CORNER ROUNDING – Haas Lathe

- 401 – INVALID TANGENT IN GROUP 1 CORNER ROUNDING OR CHAMFERING – Haas Mill

- 402 – POSSIBLE CORRUPTED FILE

- 403 – TOO MANY PROGS

- 404 – RS-232 NO PROG NAME

- 405 – RS-232 ILLEGAL PROG NAME

- 406 – RS-232 MISSING CODE

- 407 – RS-232 INVALID CODE

- 408 – RS-232 NUMBER RANGE ERROR

- 409 – RS-232 INVALID N CODE – Haas Lathe

- 409 – FILE INVALID N CODE – Haas Mill

- 410 – RS-232 INVALID V CODE – Haas Lathe

- 410 – FILE INVALID V CODE – Haas Mill

- 411 – RS-232 EMPTY PROG

- 412 – RS-232 UNEXPECTED END OF INPUT

- 413 – RS-232 LOAD INSUFFICIENT MEMORY

- 414 – RS-232 BUFFER OVERFLOW

- 415 – RS-232 OVERRUN

- 416 – RS-232 PARITY ERROR

- 417 – RS-232 FRAMING ERROR

- 418 – RS-232 BREAK

- 419 – INVALID FUNCTION FOR DNC

- 420 – PROGRAM NUMBER MISMATCH

- 421 – NO VALID POCKETS – Haas Mill

- 422 – POCKET TABLE ERROR – Haas Mill

- 423 – SERVO BAR EOB SWITCH POSITION UNKNOWN – Haas Lathe

- 423 – X SCALE/SCREW MISMATCH – Haas Mill

- 424 – SERVO BAR METRIC UNSUPPORTED – Haas Lathe

- 424 – Y SCALE/SCREW MISMATCH – Haas Mill

- 425 – SERVO BAR LENGTH UNKNOWN – Haas Lathe

- 425 – Z SCALE/SCREW MISMATCH – Haas Mill

- 426 – SERVO BAR ILLEGAL CODE G105 – Haas Lathe

- 426 – A SCALE/SCREW MISMATCH – Haas Mill

- 427 – INTERRUPT OVERRUN

- 428 – SERVO BAR SWITCH FAILURE – Haas Lathe

- 429 – DISK DIR INSUFFICIENT MEMORY

- 430 – FILE BEGINNING/END MARKER MISSING – Haas Lathe

- 430 – FILE UNEXPECTED END OF INPUT – Haas Mill

- 431 – DISK NO PROG NAME – Haas Lathe

- 431 – FILE NO PROG NAME – Haas Mill

- 432 – DISK ILLEGAL PROG NAME – Haas Lathe

- 432 – FILE ILLEGAL PROG NAME – Haas Mill

- 433 – DISK EMPTY PROG – Haas Lathe

- 433 – FILE EMPTY PROG – Haas Mill

- 434 – DISK LOAD INSUFFICIENT MEMORY – Haas Lathe

- 434 – FILE LOAD INSUFFICIENT MEMORY – Haas Mill

- 435 – DISK ABORT

- 436 – DISK FILE NOT FOUND

- 437 – TAILSTOCK UNDERSHOOT – Haas Lathe

- 438 – TAILSTOCK MOVED WHILE HOLDING PART – Haas Lathe

- 439 – TAILSTOCK FOUND NO PART – Haas Lathe

- 440 – SERVO BAR MAX PARTS REACHED – Haas Lathe

- 441 – SERVO BAR MAX BARS REACHED – Haas Lathe

- 442 – SERVO BAR MAX LENGTH REACHED – Haas Lathe

- 443 – SERVO BAR ALREADY NESTED – Haas Lathe

- 444 – REGEN ON TOO LONG – Haas Mill

- 445 – SERVO BAR FAULT – Haas Lathe

- 446 – SERVO BAR BAR TOO LONG – Haas Lathe

- 447 – SERVO BAR BAR IN WAY – Haas Lathe

- 448 – SERVO BAR OUT OF BARS – Haas Lathe

- 450 – BAR FEEDER FAULT – Haas Lathe

- 451 – BAR FEEDER SPINDLE INTERLOCK – Haas Lathe

- 452 – SERVO BAR GEARMOTOR TIMEOUT – Haas Lathe

- 453 – C AXIS ENGAGED – Haas Lathe

- 454 – C AXIS NOT ENGAGED – Haas Lathe

- 455 – G112 BLOCK ENDS W/O CANCEL CUTTER COMP – Haas Lathe

- 456 – PARAMETER CONFLICT – Haas Lathe

- 457 – AUX AXIS IS ENABLED

- 458 – LINEAR SCALES ENABLED WITHOUT MOTIF – Haas Mill

- 459 – APL DOOR FAULT – Haas Lathe

- 460 – APL ILLEGAL CODE – Haas Lathe

- 461 – APL GRIPPER TIMEOUT – Haas Lathe

- 462 – U OVER TRAVEL RANGE – Haas Lathe

- 463 – V OVER TRAVEL RANGE – Haas Lathe

- 464 – W OVER TRAVEL RANGE – Haas Lathe

- 468 – U LIMIT SWITCH – Haas Lathe

- 469 – V LIMIT SWITCH – Haas Lathe

- 470 – W LIMIT SWITCH – Haas Lathe

- 471 – OUT OF TOOLS – Haas Mill

- 472 – ATM FAULT – Haas Mill

- 473 – INVALID GEOMETRY – Haas Lathe

- 474 – G02 OR G03 NOT ALLOWED WITH G143 – Haas Mill

- 485 – USB RESET OCCURRED

- 486 – USB TIMEOUT OCCURRED

- 487 – USB DEVICE INAPPROPRIATELY UNMOUNTED

- 501 – TOO MANY ASSIGNMENTS IN ONE BLOCK

- 502 – [ OR = NOT FIRST TERM IN EXPRESSN

- 503 – ILLEGAL MACRO VARIABLE REFERENCE

- 504 – UNBALANCED BRACKETS IN EXPRESSION

- 505 – VALUE STACK ERROR

- 506 – OPERAND STACK ERROR

- 507 – TOO FEW OPERANDS ON STACK

- 508 – DIVISION BY ZERO

- 509 – ILLEGAL MACRO VARIABLE USE

- 510 – ILLEGAL OPERATOR OR FUNCTION USE

- 511 – UNBALANCED RIGHT BRACKETS

- 512 – ILLEGAL ASSIGNMENT USE

- 513 – VARIABLE REFERENCE NOT ALLOWED WITH N OR O

- 514 – ILLEGAL MACRO ADDRESS REFERENCE

- 515 – TOO MANY CONDITIONALS IN A BLOCK

- 516 – ILLEGAL CONDITIONAL OR NO THEN

- 517 – EXPRSN. NOT ALLOWED WITH N OR O

- 518 – ILLEGAL MACRO EXPRESSION REFERENCE

- 519 – TERM EXPECTED

- 520 – OPERATOR EXPECTED

- 521 – ILLEGAL FUNCTIONAL PARAMETER

- 522 – ILLEGAL ASSIGNMENT VAR OR VALUE

- 523 – CONDITIONAL REQUIRED PRIOR TO THEN

- 524 – END FOUND WITH NO MATCHING DO

- 525 – VAR. REF. ILLEGAL DURING MOVEMENT

- 526 – COMMAND FOUND ON DO/END LINE

- 527 – = NOT EXPECTED OR THEN REQUIRED

- 528 – PARAMETER PRECEDES G65

- 529 – ILLEGAL G65 PARAMETER

- 530 – TOO MANY I, J, or K’S IN G65

- 531 – MACRO NESTING TOO DEEP

- 532 – UNKNOWN CODE IN POCKET PATTERN

- 533 – MACRO VARIABLE UNDEFINED

- 534 – DO OR END ALREADY IN USE

- 535 – ILLEGAL DPRNT STATEMENT

- 536 – COMMAND FOUND ON DPRNT LINE

- 537 – RS-232 ABORT ON DPRNT

- 538 – MATCHING END NOT FOUND

- 539 – ILLEGAL GOTO

- 540 – MACRO SYNTAX NOT ALLOWED

- 541 – MACRO ALARM

- 542 – OPERATION NOT AVAILABLE

- 600 – CODE NOT EXPECTED IN THIS CONTEXT – Haas Lathe

- 600 – U OVER TRAVEL RANGE – Haas Mill

- 601 – MAXIMUM PQ BLOCKS EXCEEDED – Haas Lathe

- 601 – V OVER TRAVEL RANGE – Haas Mill

- 602 – NON-MONOTONOUS PQ BLOCKS IN X – Haas Lathe

- 602 – W OVER TRAVEL RANGE – Haas Mill

- 603 – NON-MONOTONOUS PQ BLOCKS IN Z – Haas Lathe

- 603 – U LIMIT SWITCH – Haas Mill

- 604 – NON-MONOTONOUS ARC IN PQ BLOCK – Haas Lathe

- 604 – V LIMIT SWITCH – Haas Mill

- 605 – INVALID TOOL NOSE ANGLE – Haas Lathe

- 605 – W LIMIT SWITCH – Haas Mill

- 606 – INVALID A CODE – Haas Lathe

- 607 – INVALID W CODE – Haas Lathe

- 608 – INVALID Q CODE

- 609 – TAILSTOCK RESTRICTED ZONE – Haas Lathe

- 609 – U SERVO ERROR TOO LARGE – Haas Mill

- 610 – G71/G72 DOMAIN NESTING EXCEEDED – Haas Lathe

- 610 – V SERVO ERROR TOO LARGE – Haas Mill

- 611 – G71/G72 TYPE I ALARM – Haas Lathe

- 611 – W SERVO ERROR TOO LARGE – Haas Mill

- 612 – G71/G72 TYPE II ALARM – Haas Lathe

- 612 – U SERVO OVERLOAD – Haas Mill

- 613 – COMMAND NOT ALLOWED IN CUTTER COMPENSATION

- 614 – V SERVO OVERLOAD – Haas Mill

- 615 – NO INTERSECTION TO OFFSETS IN CC – Haas Lathe

- 615 – W SERVO OVERLOAD – Haas Mill

- 616 – CANNED CYCLE USING P & Q IS ACTIVE – Haas Lathe

- 616 – U-AXIS MOTOR OVERHEAT – Haas Mill

- 617 – MISSING ADDRESS CODE – Haas Lathe

- 617 – V-AXIS MOTOR OVERHEAT – Haas Mill

- 618 – INVALID ADDRESS VALUE – Haas Lathe

- 618 – W-AXIS MOTOR OVERHEAT – Haas Mill

- 619 – STROKE EXCEEDS START POSITION – Haas Lathe

- 620 – C AXIS DISABLED

- 621 – C OVER TRAVEL RANGE

- 622 – C AXIS ENGAGEMENT FAILURE – Haas Lathe

- 622 – TOOL ARM FAULT – Haas Mill

- 623 – INVALID CODE IN G112 – Haas Lathe

- 624 – COMMAND NOT ALLOWED IN G14 MODE – Haas Lathe

- 625 – CAROUSEL POSITIONING ERROR – Haas Mill

- 626 – TOOL POCKET SLIDE ERROR – Haas Mill

- 627 – ATC ARM MOTION – Haas Mill

- 628 – ATC ARM POSITIONING ERROR – Haas Mill

- 629 – EXCEEDED MAX FEED PER REV – Haas Lathe

- 629 – APC-PIN CLEAR/HOME SWITCH FAULT – Haas Mill

- 630 – APC-DOOR SW FAULT-SWITCH NOT EQUAL TO SOLENOID – Haas Mill

- 631 – PALLET NOT CLAMPED – Haas Mill

- 632 – APC-UNCLAMP ERROR – Haas Mill

- 633 – APC-CLAMP ERROR – Haas Mill

- 634 – APC-MISLOCATED PALLET – Haas Mill

- 635 – APC-PAL NUM CONFLICT REC & CH – Haas Mill

- 636 – APC UNLOAD-SWITCH MISSED PAL 1 – Haas Mill

- 637 – APC UNLOAD-SWITCH MISSED PAL 2 – Haas Mill

- 638 – APC-DOOR NOT OPEN – Haas Mill

- 639 – APC-DOOR NOT CLOSED – Haas Mill

- 640 – APC-MISSING PALLET @ REC – Haas Mill

- 641 – APC-UNKNOWN CHAIN LOCATION – Haas Mill

- 642 – 642 APC-PIN CLEAR SWITCH FAULT – Haas Mill

- 643 – LOW BRAKE OIL A-AXIS – Haas Mill

- 644 – APC-LOW AIR PRESSURE – Haas Mill

- 645 – AMPLIFIER GROUND – Haas Mill

- 646 – VAC INPUT PHASE – Haas Mill

- 647 – REGEN LOAD SHORTED – Haas Mill

- 648 – DC BUS SHORTED – Haas Mill

- 649 – DC BUS UNDER VOLTAGE – Haas Mill

- 650 – DC BUS OVER VOLTAGE – Haas Mill

- 651 – Z AXIS IS NOT ZEROED – Haas Mill

- 652 – U ZERO RET MARGIN TOO SMALL

- 653 – V ZERO RET MARGIN TOO SMALL

- 654 – W ZERO RET MARGIN TOO SMALL

- 655 – MISMATCH AXIS WITH I, K CHAMFERING – Haas Lathe

- 655 – U CABLE FAULT – Haas Mill

- 656 – INVALID I, K, OR R IN G01 – Haas Lathe

- 656 – V CABLE FAULT – Haas Mill

- 657 – NOT ONE AXIS MOVE WITH CHAMFERING – Haas Lathe

- 657 – W CABLE FAULT – Haas Mill

- 658 – INVALID MOVE AFTER CHAMFERING – Haas Lathe

- 658 – U PHASING ERROR – Haas Mill

- 659 – NOT ONE AXIS MOVE WITH CHAMFERING – Haas Lathe

- 659 – V PHASING ERROR – Haas Mill

- 660 – W PHASING ERROR – Haas Mill

- 661 – U TRANSITION FAULT – Haas Mill

- 662 – V TRANSITION FAULT – Haas Mill

- 663 – W TRANSITION FAULT – Haas Mill

- 664 – U AXIS DISABLED

- 665 – V AXIS DISABLED – Haas Lathe

- 665 – V AXIS DISABLED – Haas Mill

- 666 – W AXIS DISABLED

- 667 – U AXIS LINEAR SCALE Z FAULT – Haas Mill

- 668 – V AXIS LINEAR SCALE Z FAULT – Haas Mill

- 669 – W AXIS LINEAR SCALE Z FAULT – Haas Mill

- 670 – TT or B OVER TRAVEL RANGE – Haas Mill

- 671 – TT or B LIMIT SWITCH – Haas Mill

- 673 – TT or B SERVO ERROR TOO LARGE – Haas Mill

- 674 – TT or B SERVO OVERLOAD – Haas Mill

- 675 – TT or B-AXIS MOTOR OVERHEAT – Haas Mill

- 676 – TT or B MOTOR Z FAULT – Haas Mill

- 677 – TT or B AXIS Z CH MISSING – Haas Mill

- 678 – TT or B AXIS DRIVE FAULT – Haas Mill

- 679 – TT or B ZERO RET MARGIN TOO SMALL – Haas Mill

- 680 – TT or B CABLE FAULT – Haas Mill

- 681 – TT or B PHASING ERROR – Haas Mill

- 682 – TT or B TRANSITION FAULT – Haas Mill

- 683 – TT or B AXIS DISABLED – Haas Mill

- 684 – TT or B AXIS LINEAR SCALE Z FAULT – Haas Mill

- 685 – V MOTOR Z FAULT – Haas Mill

- 686 – W MOTOR Z FAULT – Haas Mill

- 687 – U MOTOR Z FAULT – Haas Mill

- 688 – U AXIS Z CH MISSING – Haas Mill

- 689 – V AXIS Z CH MISSING – Haas Mill

- 690 – W AXIS Z CH MISSING – Haas Mill

- 691 – U AXIS DRIVE FAULT – Haas Mill

- 692 – V AXIS DRIVE FAULT – Haas Mill

- 693 – W AXIS DRIVE FAULT – Haas Mill

- 694 – ATC SWITCH FAULT – Haas Mill

- 695 – ATC DOUBLE-ARM CYLINDER TIME OUT – Haas Mill

- 696 – ATC MOTOR TIME OUT – Haas Mill

- 697 – ATC MOTOR FAULT – Haas Mill

- 698 – ATC PARAMETER ERROR – Haas Mill

- 701 – U SERVO ERROR TOO LARGE MOCON2 – Haas Lathe

- 702 – V SERVO ERROR TOO LARGE – Haas Lathe

- 703 – W SERVO ERROR TOO LARGE MOCON2 – Haas Lathe

- 704 – Sp SERVO ERROR TOO LARGE – Haas Lathe

- 705 – Tt SERVO ERROR TOO LARGE MOCON2 – Haas Lathe

- 706 – Ss SERVO ERROR TOO LARGE MOCON2 – Haas Lathe

- 707 – J SERVO ERROR TOO LARGE MOCON2 – Haas Lathe

- 708 – S SERVO ERROR TOO LARGE MOCON2 – Haas Lathe

- 711 – U SERVO OVERLOAD MOCON2 – Haas Lathe

- 712 – V SERVO OVERLOAD – Haas Lathe

- 713 – W SERVO OVERLOAD MOCON2 – Haas Lathe

- 714 – Sp SERVO OVERLOAD – Haas Lathe

- 715 – Tt SERVO OVERLOAD MOCON2 – Haas Lathe

- 716 – Ss SERVO OVERLOAD MOCON2 – Haas Lathe

- 717 – J SERVO OVERLOAD MOCON2 – Haas Lathe

- 718 – S SERVO OVERLOAD MOCON2 – Haas Lathe

- 721 – U-AXIS MOTOR OVERHEAT MOCON2 – Haas Lathe

- 722 – V-AXIS MOTOR OVERHEAT – Haas Lathe

- 723 – W-AXIS MOTOR OVERHEAT MOCON2 – Haas Lathe

- 724 – Sp MOTOR OVERHEAT – Haas Lathe

- 725 – Tt MOTOR OVER HEAT MOCON2 – Haas Lathe

- 726 – Ss MOTOR OVER HEAT MOCON2 – Haas Lathe

- 727 – J-AXIS MOTOR OVERHEAT MOCON2 – Haas Lathe

- 728 – S-AXIS MOTOR OVERHEAT MOCON2 – Haas Lathe

- 731 – U MOTOR Z FAULT MOCON2 – Haas Lathe

- 732 – V MOTOR Z FAULT – Haas Lathe

- 733 – W MOTOR Z FAULT MOCON2 – Haas Lathe

- 734 – Sp MOTOR Z FAULT – Haas Lathe

- 735 – Tt MOTOR Z FAULT MOCON2 – Haas Lathe

- 736 – Ss MOTOR Z FAULT MOCON2 – Haas Lathe

- 737 – J MOTOR Z FAULT MOCON2 – Haas Lathe

- 738 – S MOTOR Z FAULT MOCON2 – Haas Lathe

- 741 – U AXIS Z CH MISSING MOCON2 – Haas Lathe

- 742 – V AXIS Z CH MISSING – Haas Lathe

- 743 – W AXIS Z CH MISSING MOCON2 – Haas Lathe

- 744 – Sp AXIS Z CH MISSING – Haas Lathe

- 745 – Tt AXIS Z CH MISSING MOCON2 – Haas Lathe

- 746 – Ss AXIS Z CH MISSING MOCON2 – Haas Lathe

- 747 – J AXIS Z CH MISSING MOCON2 – Haas Lathe

- 748 – S AXIS Z CH MISSING MOCON2 – Haas Lathe

- 751 – U AXIS DRIVE FAULT MOCON2 – Haas Lathe

- 752 – V AXIS DRIVE FAULT – Haas Lathe

- 753 – W AXIS DRIVE FAULT MOCON2 – Haas Lathe

- 754 – Sp AXIS DRIVE FAULT – Haas Lathe

- 755 – Tt AXIS DRIVE FAULT MOCON2 – Haas Lathe

- 756 – Ss AXIS DRIVE FAULT MOCON2 – Haas Lathe

- 757 – J AXIS DRIVE FAULT MOCON2 – Haas Lathe

- 758 – S AXIS DRIVE FAULT MOCON2 – Haas Lathe

- 761 – U CABLE FAULT MOCON2 – Haas Lathe

- 762 – V CABLE FAULT – Haas Lathe

- 763 – W CABLE FAULT MOCON2 – Haas Lathe

- 764 – Sp CABLE FAULT – Haas Lathe

- 765 – Tt CABLE FAULT MOCON2 – Haas Lathe

- 766 – Ss CABLE FAULT MOCON2 – Haas Lathe

- 767 – J CABLE FAULT MOCON2 – Haas Lathe

- 768 – S CABLE FAULT MOCON2 – Haas Lathe

- 771 – U PHASING ERROR MOCON2 – Haas Lathe

- 772 – V PHASING ERROR – Haas Lathe

- 773 – W PHASING ERROR MOCON2 – Haas Lathe

- 774 – Sp PHASING ERROR – Haas Lathe

- 775 – Tt PHASING ERROR MOCON2 – Haas Lathe

- 776 – Ss PHASING ERROR MOCON2 – Haas Lathe

- 777 – J PHASING ERROR MOCON2 – Haas Lathe

- 778 – S PHASING ERROR MOCON2 – Haas Lathe

- 781 – U TRANSITION FAULT MOCON2 – Haas Lathe

- 782 – V TRANSITION FAULT – Haas Lathe

- 783 – W TRANSITION FAULT MOCON2 – Haas Lathe

- 784 – SP MOT ENC TRANSITION FAULT – Haas Lathe

- 785 – Tt TRANSITION FAULT MOCON2 – Haas Lathe

- 786 – Ss TRANSITION FAULT MOCON2 – Haas Lathe

- 787 – J TRANSITION FAULT MOCON2 – Haas Lathe

- 788 – S TRANSITION FAULT MOCON2 – Haas Lathe

- 791 – COMM. FAILURE WITH MOCON2

- 792 – MOCON2 WATCHDOG FAULT

- 796 – SUB SPINDLE NOT TURNING – Haas Lathe

- 797 – SUB SPINDLE ORIENTATION FAULT – Haas Lathe

- 799 – UNKNOWN MOCON2 ERROR – Haas Mill

- 800 – P AND Q EXCEEDED MEMORY – Haas Lathe

- 801 – NO BLOCK DELETES BETWEEN P AND Q – Haas Lathe

- 802 – NEGATIVE R AND C VALUES NOT ALLOWED

- 808 – AUTOMATIC PROBE ARM FAULT

- 809 – PROBE ARM SWITCH FAULT

- 810 – PROBE ARM CHUCK CONFLICT

- 900 – A PARAMETER HAS BEEN CHANGED

- 901 – PARAMETERS HAVE BEEN LOADED BY DISK

- 902 – PARAMETERS HAVE BEEN LOADED BY RS232

- 903 – CNC MACHINE POWERED UP

- 904 – ATC AXIS VISIBLE – Haas Mill

- 905 – NO P CODE IN M14, M15, M36 – Haas Mill

- 906 – INVALID P CODE IN M14, M15, M36 OR M50 – Haas Mill

- 907 – APC UNLOAD-SWITCH MISSED PAL 3 – Haas Mill

- 908 – APC UNLOAD-SWITCH MISSED PAL 4 – Haas Mill

- 909 – APC-PROGRAM NOT LISTED – Haas Mill

- 910 – APC-PROGRAM CONFLICT – Haas Mill

- 911 – APC-PAL LOAD/UNLOAD AT ZERO – Haas Mill

- 912 – APC-NO P CODE OR Q CODE FOR M46 – Haas Mill

- 913 – APC-NO P CODE OR Q CODE FOR M49 – Haas Mill

- 914 – APC-INVALID P CODE – Haas Mill

- 915 – APC-ILLEGAL NESTING G188 or M48 – Haas Mill

- 916 – APC-NEGATIVE PAL PRIORITY INDEX – Haas Mill

- 917 – APC-NUMBER OF PALLETS IS ZERO – Haas Mill

- 918 – APC LOAD-SWITCH MISSED PAL 1 – Haas Mill

- 919 – APC LOAD-SWITCH MISSED PAL 2 – Haas Mill

- 920 – APC LOAD-SWITCH MISSED PAL 3 – Haas Mill

- 921 – APC LOAD-SWITCH MISSED PAL 4 – Haas Mill

- 922 – APC-TABLE NOT DECLARED – Haas Mill

- 923 – LOW OIL PRESSURE – Haas Lathe

- 923 – A INDEXER IS NOT AT THE PROPER INCREMENTAL POSITION – Haas Mill

- 924 – SS LOW LUBE OR LOW PRESSURE – Haas Lathe

- 924 – B INDEXER IS NOT AT THE PROPER INCREMENTAL POSITION – Haas Mill

- 925 – A INDEXER IS NOT FULLY IN THE UP POSITION – Haas Mill

- 926 – B INDEXER IS NOT FULLY IN THE UP POSITION – Haas Mill

- 927 – ILLEGAL G1 CODE FOR ROTARY INDEXER – Haas Mill

- 932 – BAR 100- ZERO VALUE – Haas Lathe

- 933 – BAR 100- MAXIMUM PARTS COMPLETED – Haas Lathe

- 934 – BAR 100- CURRENT BAR FINISHED – Haas Lathe

- 935 – BAR 100 FAULT – Haas Lathe

- 937 – INPUT LINE POWER FAULT

- 938 – LANGUAGES LOADED

- 939 – LANGUAGES FAILED TO LOAD

- 940 – SIDE MOUNT CAROUSEL ERROR – Haas Mill

- 941 – POCKET-TOOL TABLE ERROR – Haas Mill

- 942 – CAROUSEL POSITION TIMEOUT – Haas Mill

- 943 – UNPROCESSED QUEUE CELL IN TOOL CHANGE – Haas Mill

- 944 – INDEXER OUT OF POSITION – Haas Mill

- 945 – APC-LIFT FRAME DOWN TIMEOUT – Haas Mill

- 946 – APC-PALLET CLAMP TIMEOUT – Haas Mill

- 947 – APC-PALLET UNCLAMP TIMEOUT – Haas Mill

- 948 – APC-SOFTWARE ERROR – Haas Mill

- 949 – APC-AXIS VISIBLE – Haas Mill

- 950 – APC-ILLEGAL SWITCH CONDITION, LIFT FRAME – Haas Mill

- 951 – APC-ILLEGAL SWITCH CONDITION, PALLET CLAMP – Haas Mill

- 952 – APC-MISLOCATED LIFT FRAME – Haas Mill

- 953 – APC-MISLOCATED PALLET CLAMP – Haas Mill

- 954 – APC-INCOMPLETE PALLET CHANGE – Haas Mill

- 955 – APC-INVALID PALLET CHANGER TYPE – Haas Mill

- 956 – APC-LIFT FRAME UP TIMEOUT – Haas Mill

- 957 – APC-SWITCH FAULT – Haas Mill

- 958 – TOOL OFS WEAR HAS BEEN CHANGED

- 959 – NON-INDEXER POSITION – Haas Mill

- 960 – INDEXER SWITCH NOT FOUND IN TIME – Haas Mill

- 961 – FLOPPY OFFSET NOT FOUND

- 962 – UNABLE TO RETRIEVE FILE INFORMATION

- 963 – UNABLE TO FNC FROM THIS DEVICE

- 964 – TOOL TURRET ROTATE FAULT

- 965 – TURRET CLAMP/UNCLAMP FAULT

- 967 – SKBIF COMMUNICATION FAULT

- 968 – DOOR HOLD OVERRIDE ENGAGED

- 970 – NO AXIS COMMANDED IN FEED CODE

- 971 – FAILED LOAD

- 976 – PALLET POOL-INVALID PALLET

- 982 – ZERO ANGLE MOVE

- 983 – VD OVER CURRENT – Haas Mill

- 984 – VD SHORT CIRCUIT – Haas Mill

- 985 – DC BUS OV CHRG – Haas Mill

- 986 – CALIBRATION FAILED

- 991 – AMPLIFIER OVER TEMPERATURE

- 992 – AMPLIFIER OVER CURRENT

- 993 – AMPLIFIER SHORT CIRCUIT

- 994 – AMPLIFIER OVERLOAD

- 995 – AMPLIFIER CURRENT ERROR TOO LARGE

- 995 – ERROR TOO LARGE – Haas Mill

- 996 – TAIL STOCK MUST BE ZERO RETURNED – Haas Lathe

- 997 – TOO MANY FILES HAVE BEEN OPENED ON THE CURRENT DEVICE

- 998 – A FILE COULD NOT BE OPENED